VEPLA PIPELINE ANCHOR

Vertically Embedded Plate Anchor

VEPLA Pipeline Anchor

The simple pipeline walking solution

The problem of pipeline walking has been around for many years and has been investigated by a several Joint Industry Projects, most notably the series of Safebuck JIPs to research the mechanisms that lead to pipeline walking and to better understand the how and why this occurs. While this research has given a good understanding of the “when and how” of pipeline walking little attention has been paid to solutions.

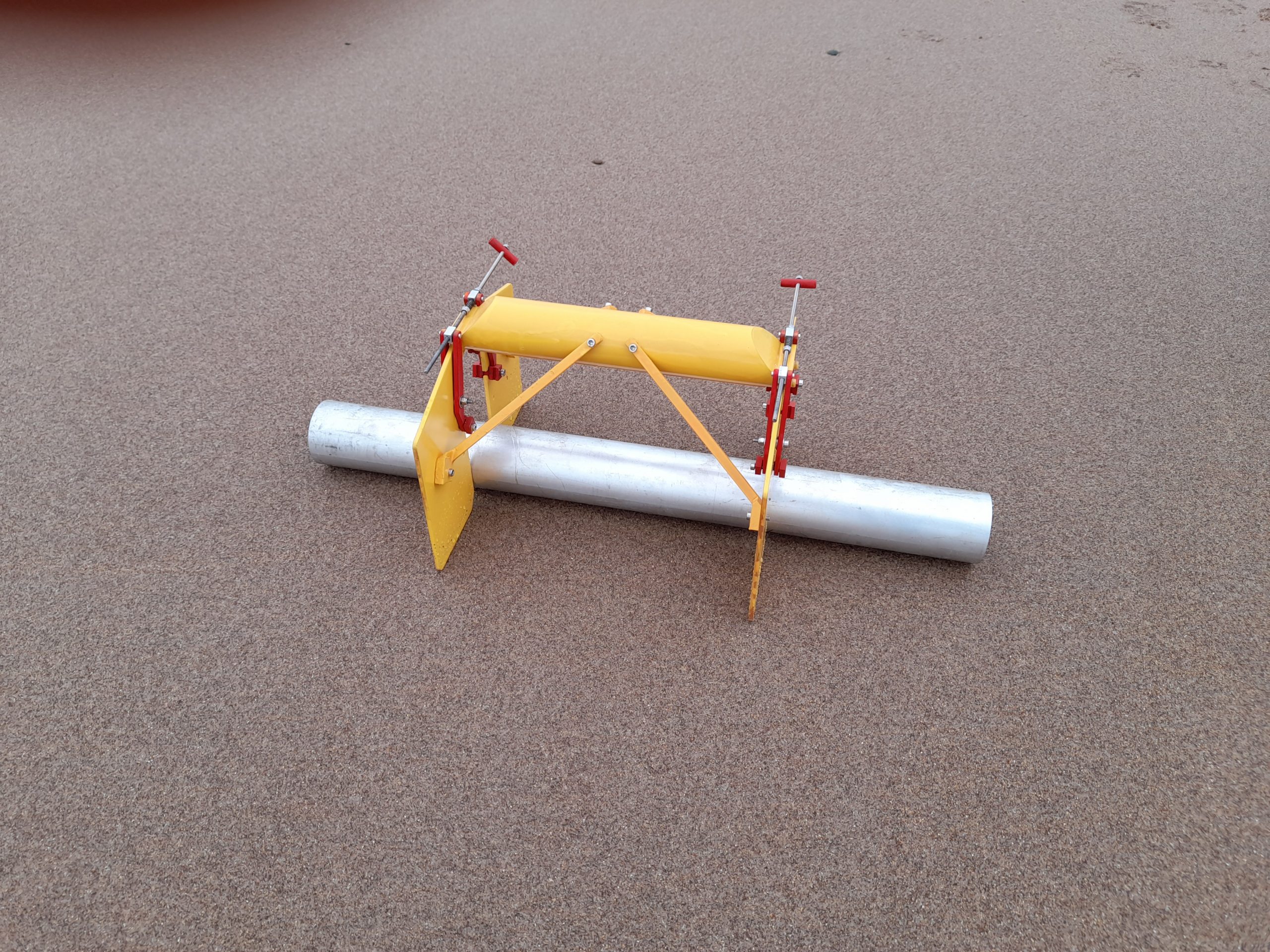

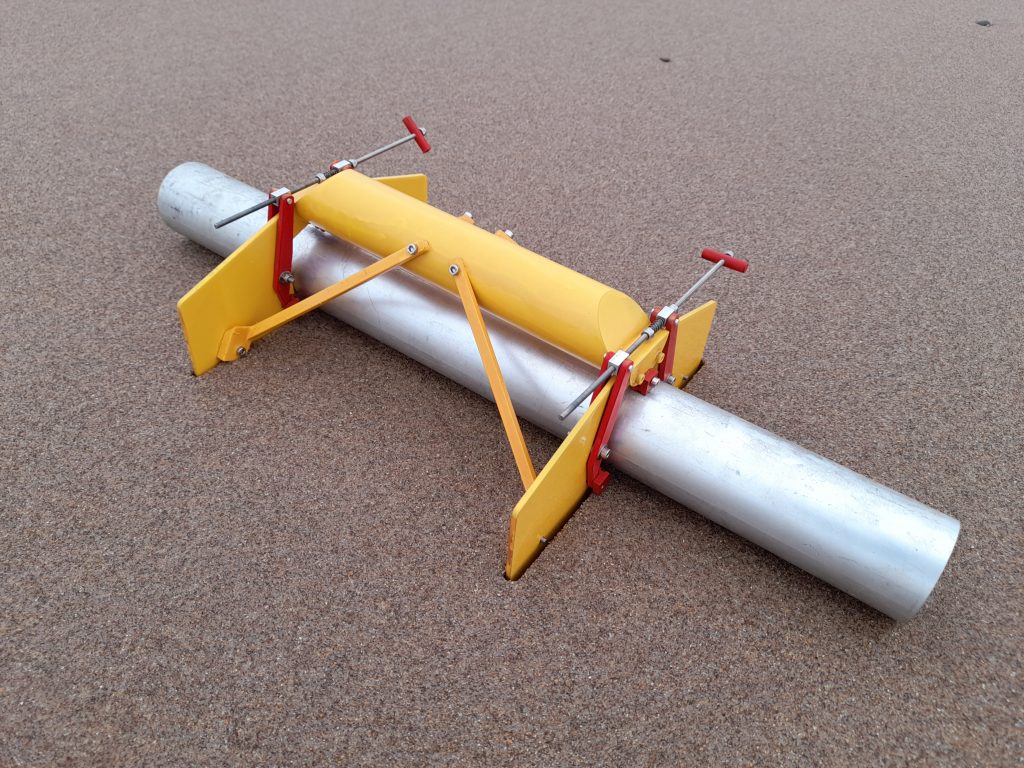

The concept of a Vertically Embedded Plate Anchor, or VEPLA came from an idea during a review of possible anchoring methods. The concept is simplicity itself, comprising two vertical plates connected by a longitudinal beam.

The VEPLA is placed over the pipeline and allowed to penetrate under self-weight into the seabed soils. As pipeline walking is mainly associated with deep water very soft clay projects, the self-weight required is relatively low.

Key features of the VEPLA concept are the ease of installation from a typical IMR vessel with a workclass ROV. The anchor is simply lowered by crane from the vessel, and penetrates into the seabed under self-weight. Once in position on the pipeline the ROV simply uses its manipulator to close the pipe clamps with the clamping pads designed to self-clear any soft clay that may be present. The clamps form a three jaw chuck allowing an even and reliable clamping pressure to be achieved, to resist the axial motion of the pipeline. The system has been specifically designed to be installed on either a new pipeline, or one which has been in service and a walking problem has developed over time.

A single unit can typically achieve a resistance of 15 tonnes depending simply on soil strength and size of the plates which can be easily adapted to suit project specific requirements. This resistance is available immediately on installation with no requirement to wait for medium term The design has also been developed to reduce the return resistance when the pipeline operation is paused. This provides some significant benefits, and further aids eliminating walking.

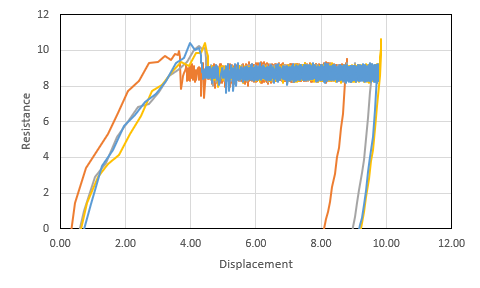

Model testing has been completed using the centrifuge at Dundee University to calibrate the resistance models developed and to demonstrate the key geotechnical characteristics of the concept. PACE consider the technology ready for full offshore deployment. With our partners, we can provide a full package including pipeline analysis and project specific design of the VEPLA with either manufacturing or license a set of full fabrication drawings for manufacture in country, helping meet local content requirements. Our partners in this include Crondall Subsea, who bring many years of experience of pipeline walking analysis and experience of the Safebuck project. For offshore installation and operations support we work with Helix Robotics Solutions. With their support we can either simply advise on offshore procedures, or we can provide a full offshore crew to assist installation.